Receipt Printer Paper Guidelines

The 1ST (7350-F307) Self-Service Receipt Printer requires an NCR qualified thermal paper to ensure proper printer operation. This section provides guidelines in selecting a thermal receipt paper for a 1ST (7350-F307) Self-Service Receipt Printer.

! Important: NCR does not test individual suppliers’ papers. Users are responsible of for ensuring that the paper they intend to use does not have a detrimental effect on the printers. Use of such paper invalidates any warranty related to the performance of the printer.

|

Requirement |

Specifications |

|---|---|

|

Quality Control |

Supplier must have processes and procedures that have mechanisms to stop and recall paper that is out of the agreed specification to ensure consistent paper quality. |

|

Pre-printed Receipt paper |

Testing pre-printed receipt paper is required to determine if printed artwork on either side of the paper has a detrimental effect to the printer. Any changes in the design should be retested. |

|

Image life |

Specify a life expectancy of the paper that is suitable for intended application. |

|

End of Roll Indicator |

Aside from the "paper low" warning capability of the printer, some users define a visual indication to inform operators when to change the roll. This can be a pre-printed line at a set length before the end of the roll. Ensure that the properties of this line are not detrimental to the printer's life expectancy. |

|

Product essential functionality/features that should be included in customer’s specification for receipt paper. |

•The coating should not cause undue wear to the print head. •The surface area of the paper should be smooth. •All edges must be correctly cut and smooth. •There should be no mottling or foreign body contamination. •There should be no dust on the surface of the paper that could cause damage to printer or nearby equipment. •There should be suitable coatings to protect the paper from UV light, water, oils etc. •Thermal coating residue should not transfer to the print head when heated. •Paper must allow for crisp lines to be produced when the paper is heated. •Should be sourced in accordance with your health and safety, and environmental policies, and in adherence to any local regulations. •Paper should be suitably packed and protected so that it does not get damaged during transport. |

|

Chemical in Paper |

The chemical elements of paper, coating and inks shall not exceed the following amount: •Titanium dioxide, TiO2 0 ppm (max) •Silicon dioxide, SiO2 0 ppm (max) •Mullite, 3Al2O32SiO2 0 ppm (max) •Sodium, Na 1050 ppm (max) •Chloride, Cl 500 ppm (max) •Potassium, K 250 ppm (max) •Suflate, SO4 800 ppm (max) •Ammonium, NH4 800 ppm (max) The chemicals listed here are not exhaustive and other chemicals may reduce the life expectancy of the printer and/or print head. |

|

Roll Width |

80 mm (+0.5 / -1.2 mm) |

|

Roll Diameter |

144.8 mm max |

|

Roll Length |

Approx. 280 m |

|

Core Inner Diameter |

12.7 mm (Typical) |

|

Core Outer Diameter |

18 mm (Typical) |

|

Core Width |

79 mm (Typical) |

|

Core Material |

Plastic or Chipboard |

|

Paper weight |

44-70 gsm |

|

Paper caliper thickness |

44-70 um |

|

Paper Winding Direction |

Thermal Coating facing Out |

|

Smoothness |

300 sec min (ISO 5627) |

|

Dynamic sensitivity |

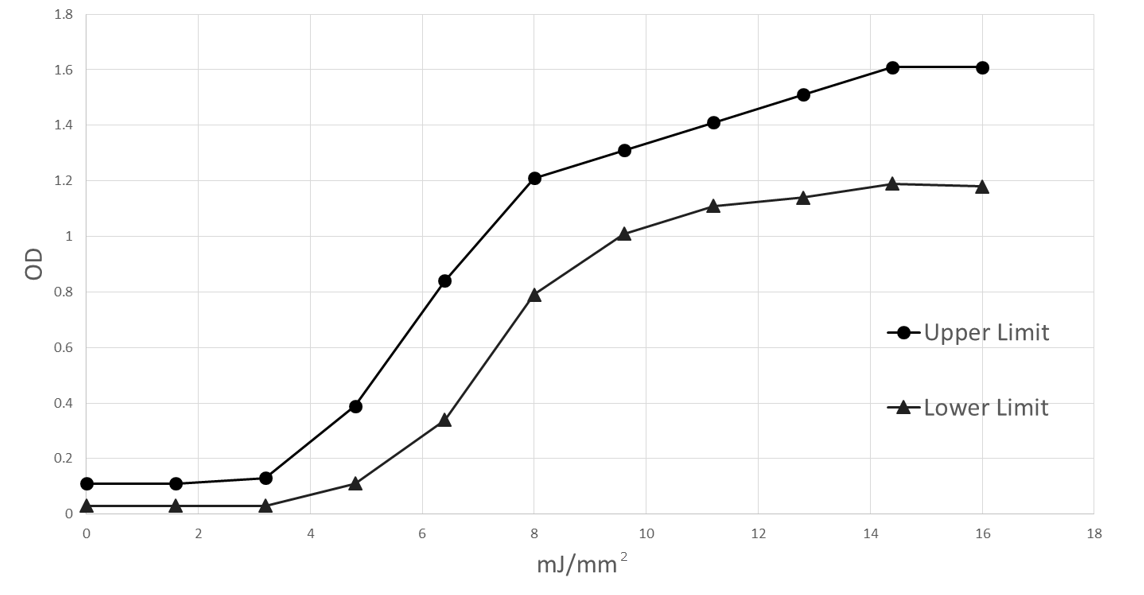

Energy to be equal or less than 11.2 mJ/mm2 at 1.1 OD Note: For more information, refer to the Dynamic Sensitivity Range graph below. |

|

Brightness |

Less than 85% |

Dynamic Sensitivity Range