Ordering Paper and Supplies

Selecting thermal receipt paper

NCR products are designed for the global market and are tested to determine performance parameters, such as thermal head and cutter life expectancy, against defined mill grade papers at the time of release. NCR printers require qualified thermal paper to ensure proper printer operation. This section provides guidelines in selecting a thermal receipt paper for NCR printers.

The paper rolls must meet the guidelines provided in this section, and the paper must not be attached at the core to avoid damaging the printer when the paper is exhausted.

NCR does not test individual suppliers’ papers. It is the responsibility of users of the printers to ensure that the paper they intend to use does not have a detrimental effect on the life of the printers. Use of such paper invalidates any warranty related to the performance of the printer.

The following table covers key considerations (but not necessarily all) for purchasing papers.

| Requirement | Specification |

|---|---|

| Quality Control | The supplier must have processes and procedures in place to ensure that a consistent quality is always maintained. These processes and procedures should have mechanisms to stop and recall paper that is out of the agreed specification. |

| Pre–Printed Receipt paper | The addition of pre–printed artwork on either side of the paper has a potential to cause increased wear to the printer. Testing is required to determine if this has a detrimental effect. Retesting is also required if there are any changes in the paper design. |

| Image life | The paper is available with different life expectancy of the image. Ensure to specify a life expectancy that is suitable for the intended application. |

| End of Roll Indicator | As well as using the “paper low” warning capability of the printer, some users define a visual indication to assist the operator in knowing when to change the roll. Typically, this can be in the form of a pre–printed line at a set length before the end of the roll. It is important that the properties of this line are not detrimental to the printer’s life expectancy. |

| Product essential functionality and features that should be included in the customer’s specification for receipt paper | The following must be observed:

|

| Chemical in Paper | The chemical elements of the paper, coating, and inks shall not exceed the following amount:

The chemicals listed here are not exhaustive, and other chemicals may reduce the life expectancy of the printer, the print head, or both. |

| Roll Width |

|

| Roll Diameter | Maximum of 83 mm |

| Roll Length | Approximately 88 m |

| Core Inner Diameter |

|

| Core Outer Diameter | 15 to 25 mm, 18 mm (Typical). See note below this table. |

| Core Width | Maximum of 79 mm |

| Core Material | Plastic or Chipboard |

| Paper weight |

|

| Paper caliper thickness |

|

| Paper Winding Direction | Thermal coating facing out |

| Smoothness | 300 sec min (ISO 5627) |

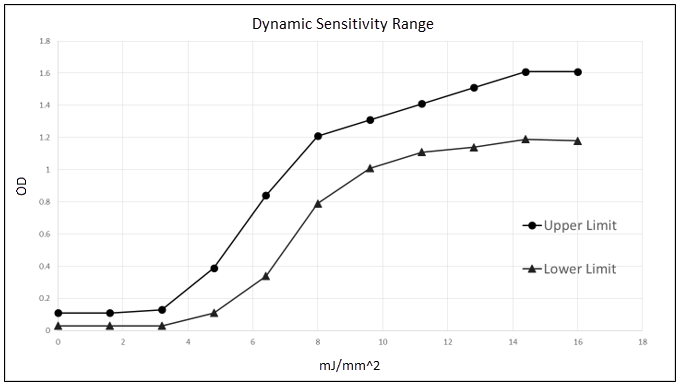

| Dynamic sensitivity | Energy to be equal to or less than 11.2 mJ/mm2 at 1.1 OD Note

For more details, refer to the Dynamic Sensitivity Range graph below. |

| Brightness | Less than 85% |

Coreless paper is not supported due to the tendency of the paper roll to collapse and increase the load placed on the printer as it attempts to feed the oblong roll.

Using an inferior grade of paper can affect the print quality, the life of printheads, and the printer mechanism.

Take note of the following:

- Printer reliability and performance are directly related to the quality of supplies used by the customer. The published reliability information for printer performance is established using supplies that meet NCR specifications.

- Thermal paper with watermarks, coupons, or advertisements printed on its front or back are not covered by NCR specifications. Some inks and printing processes work acceptably, but others do not.

- Printer problems that are caused by supplies that do not meet NCR specifications may result in expensive resolutions.

The following table provides information on other thermal papers tested with the NCR 7199 Series printer.

| Paper Manufacturer | Media Model | Notes |

|---|---|---|

| Koehler | Blue4est® KT 90 FA KT 48 PF | For more information, refer to https://www.koehlerpaper.com/en/products/Thermal-paper/ |